- Bridging the Performance Gap

- Optimise Plant and Building Performance

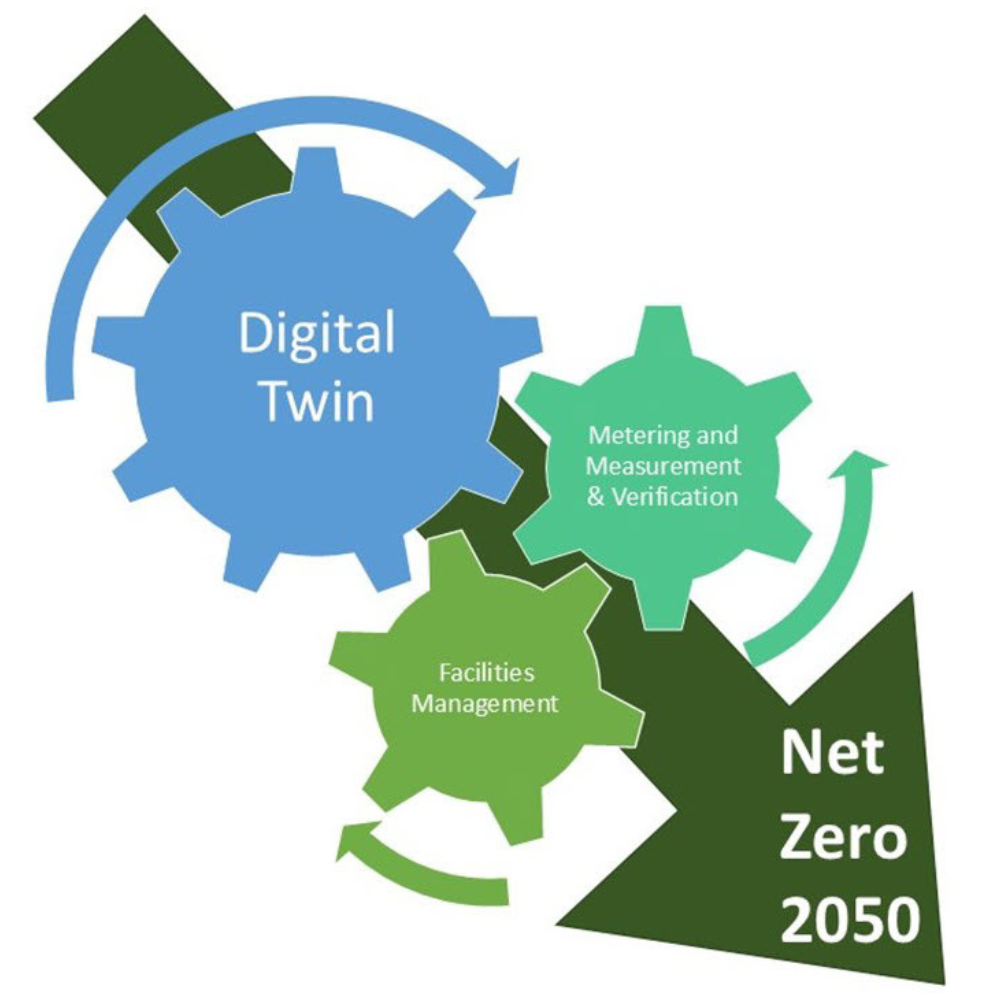

- Integration with Measurement & Verification and Facilities Management

Digital Twin Technology to Decarbonise your Building Portfolio

Using Machine Learning technology, we can create a digital replica of your building’s energy performance in a 3D virtual environment, otherwise known as a Digital Twin. This process is facilitated using data gathered from a site survey and/or metering data of the building services systems.

A Digital Twin provides a more accurate visualisation of how your building consumes energy and allows our engineers to locate pinch points quicker and propose energy reduction interventions. The level of detail provided by a Digital Twin can allow a more thorough analysis of each potential intervention which is assessed in a dynamic simulation model to provide more accurate energy and cost savings. From changing a fan in an air handling unit, to re-designing a HVAC plant room, the Digital Twin can optimise all plant performance and outline a pathway to decarbonisation which is best suited to the building’s needs and Client’s objectives.

Get Started

Lawler Sustainability have a team of in-house energy modellers and engineers experienced in providing decarbonisation pathways using Digital Twins. This process includes a detailed site audit of building fabric and building services systems, which are then re-created in a digital environment for further analysis. Lawler Vision, which is our metering and measurement & verification department, manages the energy performance of the building and feeds our ML program with data to digitally reflect the performance in a virtual environment. This digital twin allows our engineers to critically assess multiple energy saving interventions and accurately predict future performance and savings.A technical report is created outlining the path to decarbonisation using the results from the Digital Twin analysis.

We can help you along this journey with continued project management and optimisation of plant performance via our Facilities Management team.